Piemonte

Collegno

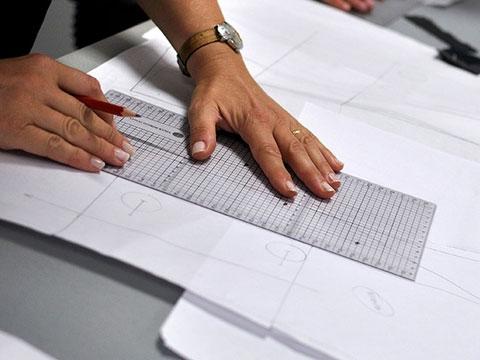

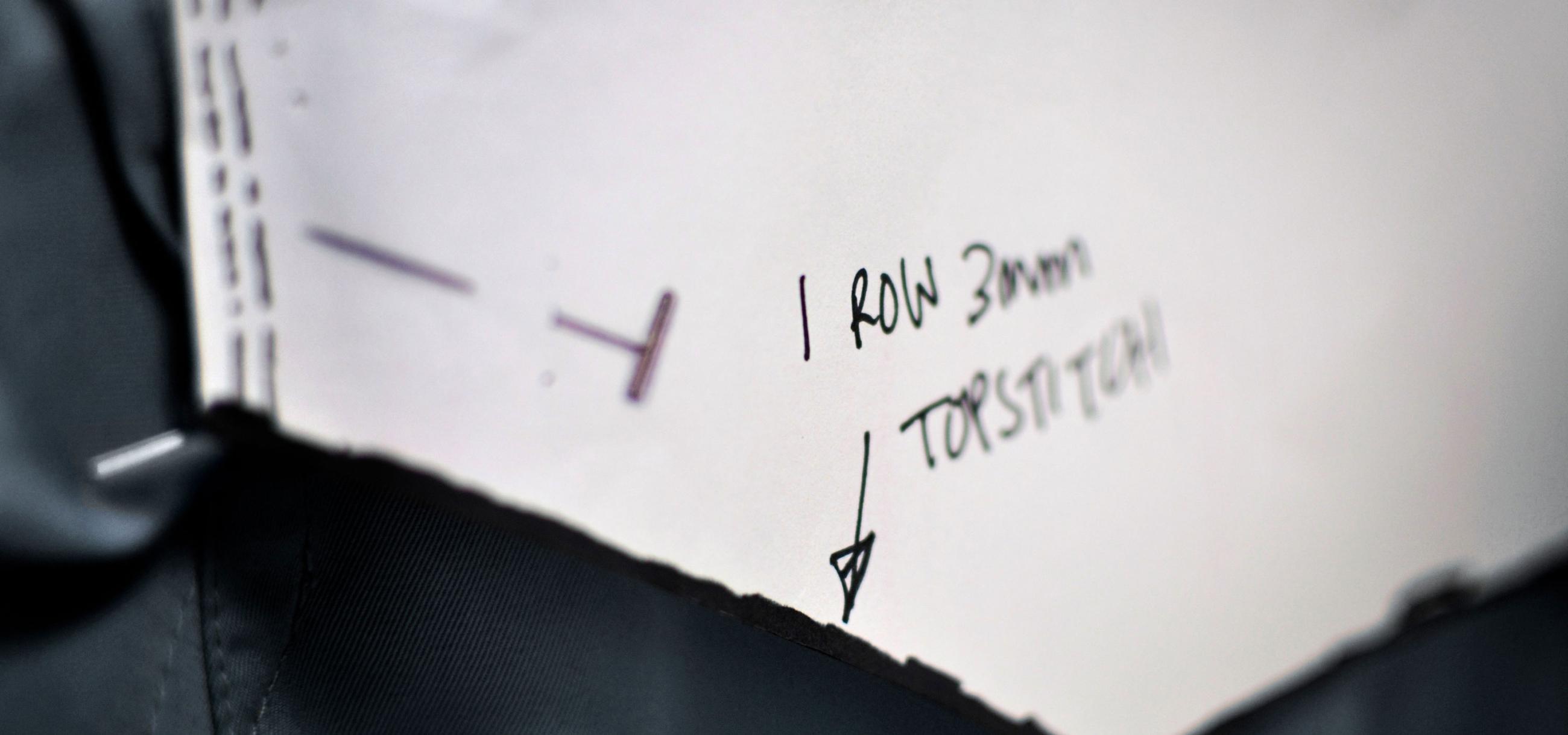

Landmark for Pattern-making, Engineering, Grading, Prototyping and Production for the most prestigious top luxury brands worldwide.

Pattern, Headquarters of Pattern Group, represents a success Made in Italy story began 25 years ago, in October 2000 in Turin, from the entrepreneurial idea of the two Founders, currently Technical Directors and Majority Shareholders of the Group, Fulvio Botto and Franco Martorella, to create a leading company in Luxury Menswear and outerwear Prototyping and Engineering.

In 2014, Pattern took over the brand ESEMPLARE, specialized in functional menswear, becoming the only property brand of the company. In 2017, a structured growth process began which led, thanks firstly to the awarding of the Elite Certification of Borsa Italiana and then to the listing on the Euronext Growth Milan Market of Borsa Italiana in 2019, to the creation of Pattern Group: the first Italian Hub of Luxury Fashion Engineering & Production, of which Pattern is headquarters

Pattern Group today represents a one-of-a-kind case in the Italian Fashion sector of a private and independent company with a long-term industrial vision.

Pattern’s identity is hinged on a balanced combination of craftsmanship and technology with a focus given to employees.

As proof of this, since 2012 an internal Code of Ethics has been adopted, and in 2013 Pattern was the very first Italian company to obtain the International Certification SA8000 Social Accountability, defining a precise company policy on Social Responsibility, Organization and Working Conditions.

Additionally, in 2021 Pattern adopted the 231 Model to establish specific self-regulation mechanisms and achieve the utmost transparency.

Pattern - Corporate Headquarters

PATTERN - Corporate Headquarters

Via Nazioni Unite 19

10093 - Collegno (TO) Italy

Tel: +39 011 4531597